Master the Magic of Printing Ink Solvents for Flawless Print

| Feb 01, 2025Have you noticed your outdoor signage or banners fading too quickly? These issues often boil down to the type of ink you’re using. If you’re tired of prints that fail to withstand harsh weather or heavy handling, it’s time to consider solvent ink printing.

Designed to deliver exceptional durability and vivid colors, printing ink solvents are a game-changer for professional printing. From creating long-lasting vehicle wraps to vibrant billboards, solvent-based inks ensure your prints remain sharp and lively no matter the conditions.

But what makes these inks so special? And how do they compare to other types of ink for printers, like water-based or sublimation ink? This guide will answer:

- What exactly are solvent-based inks and how do they work?

- How does solvent printing differ from other methods?

- When should you choose solvent printer ink for your projects?

What Is Solvent Printer Ink?

Printing ink solvents refer to inks that use chemical solvents as their primary carrier. These solvents dissolve pigments, enabling the ink to bond effectively with non-porous surfaces like vinyl, plastic, and metal. Unlike water-based alternatives, solvent inks don’t rely on water for adhesion. This makes it highly durable and resistant to environmental factors such as rain, UV exposure, and abrasion.

Typically, solvent-based ink includes:

- Pigments for color vibrancy.

- Solvents to facilitate adhesion and drying.

- Resins to enhance durability and flexibility.

How Solvents Work in Printing Inks?

In solvent inkjet printing, the solvent evaporates during the printing process, leaving behind the pigment and resin firmly bonded to the material. This evaporation ensures quick drying and robust adhesion, even on challenging surfaces like vinyl banners or vehicle wraps. The result is a durable and weatherproof finish.

Types of Solvent-Based Ink

Choosing the right printer ink is crucial for specific applications. Common options include water-based solvents, solvent-based solvents, and UV-curable solvents, each catering to different needs like solvent ink printing, digital printing, and specialty coatings.

1. Water-Based Solvents

Water-based solvents are commonly used for solvent inkjet printing, offset printing, and screen printing. These are ideal for producing vibrant colors on porous surfaces like textiles and paper.

Advantages:

- Environmentally friendly as they emit minimal harmful substances.

- Easier to clean and handle due to their water composition.

- Suitable for indoor use due to low odor and safer formulations.

Disadvantages:

- Slower drying time compared to solvent-based ink due to water evaporation.

- Limited adhesion to non-porous surfaces, reducing versatility.

- May require additional coatings to ensure durability.

2. Solvent-Based Solvents

Solvent based inks primarily use these solvents, which excel in outdoor applications like banners, vehicle wraps, and billboards. Their strong adhesion makes them suitable for non-porous surfaces like vinyl and plastics.

Advantages:

- Fast drying time, boosting productivity.

- High durability against weather conditions, UV rays, and moisture.

- Excellent print adhesion on various surfaces, ensuring quality results.

Disadvantages:

- Emit volatile organic compounds (VOCs), contributing to air pollution and health risks.

- Require proper ventilation and protective measures during use.

- Maintenance of printers can be more demanding due to residue buildup.

3. UV-Curable Solvents

Used in UV inks, these solvents are ideal for high-speed printing and industrial applications like coatings, optical materials, and wood finishes. UV-curable inks are cured instantly using ultraviolet light, enhancing production efficiency.

Advantages:

- Instant curing reduces production time significantly.

- Durable and scratch-resistant, offering a professional finish.

- Low solvent evaporation minimizes environmental impact.

Disadvantages:

- Requires specialized UV curing equipment, increasing initial costs.

- Limited compatibility with certain printer types and materials.

- Photoinitiators in UV resins can be sensitive to light exposure during storage.

When to Use Printing Ink Solvents?

Solvent-based ink offers unmatched durability, especially when exposed to outdoor conditions. It’s ideal for applications where printed materials must withstand harsh weather, sun exposure, and physical wear. Here are some important applications of Printing Ink Solvents:

1. Screen Printing

It is essential for screen printing on non-porous surfaces like metal, glass, and plastic. Its quick-drying properties and strong adhesion make it ideal for durable designs, especially outdoor exposure.

2. Vehicle Wraps and Graphics

Solvent printing excels in vehicle wraps and graphics. Its solvent-based ink adheres to vinyl, offering a glossy, durable finish that resists UV damage and abrasion. This makes it ideal for both single vehicles and fleets.

3. High-Durability Applications Requiring Weather Resistance

For outdoor signage, posters, and window graphics, solvent-based ink ensures durability. Solvent ink printing resists fading, cracking, and peeling, keeping prints vibrant and intact for extended periods.

4. Packaging Industry

Solvent printing is commonly used for printing on flexible packaging materials, such as plastic films, pouches, and labels. These inks offer strong adhesion and durability, ensuring the printed designs remain intact even after handling, shipping, and exposure to various environmental conditions.

5. Textile Printing:

In textile printing, solvent-based ink provides vibrant, durable prints that resist washing and fading. Eco solvent ink is a popular, environmentally friendly alternative, offering similar quality while reducing environmental impact. Both inks are ideal for fabrics that require long-lasting, high-quality designs.

How Solvent Inks Differ from Other Ink Types

Printing Ink Solvents offers superior durability and versatility compared to other ink types. Here’s how it compares:

1. Solvent vs. Eco-Solvent Inks:

- VOC Emissions: Traditional solvent inks emit higher VOCs, while eco solvent ink uses biodegradable solvents with lower emissions, making them more eco-friendly.

- Applications: Both excel in outdoor printing, but eco-solvent is a cleaner choice for environmentally-conscious businesses.

2. Solvent Inks vs. UV-Curable Inks:

- Curing Process: Solvent inks air-dry, while UV inks cure instantly under UV light, offering faster handling but limited material compatibility.

- Cost & Compatibility: Solvent inks are cost-effective for large prints on a variety of materials, while UV inks are suited for specific substrates.

3. Solvent Inks vs. Dye-Sublimation Inks:

- Application: Dye-sublimation inks are ideal for fabric printing, while solvent inks are better for outdoor signage and vehicle wraps.

- Weather Resistance: Solvent inks offer superior weather resistance, making them more durable for long-term outdoor use.

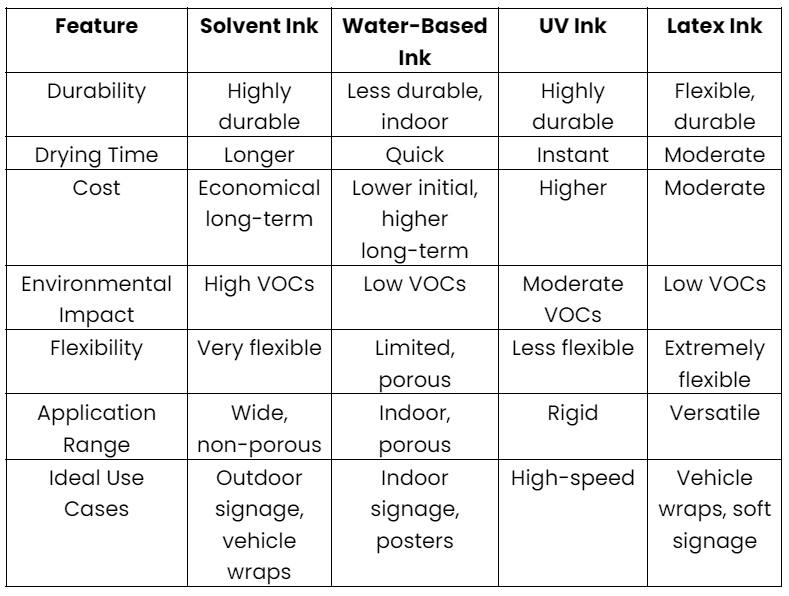

Solvent Printer Ink VS Other Printing Technologies

Choosing the right printing solution is essential for meeting specific needs. Understanding the main differences helps select the best option for your requirements.

What Makes Solvent-Based Ink Preferable?

Solvent ink printing offers several advantages, making it a preferred choice across various industries. Its durability, versatility, and cost-effectiveness make solvent-based ink an excellent option for high-quality, long-lasting prints.

1. Durability and Longevity

One of the most significant advantages of solvent ink is its exceptional durability and longevity. This printing method creates prints that can withstand harsh environmental conditions.

- Resistance to UV, Water, and Abrasion: Solvent printer ink’s pigments maintain their vibrancy even under intense sunlight and rain, a major pain point for businesses needing reliable outdoor advertising.

- Suitable for Extreme Environmental Conditions: From scorching heat to heavy rain and high humidity, its durability is crucial for outdoor signage, vehicle wraps, and billboards.

2. Versatility and Compatibility

Solvent ink is highly versatile, adhering well to vinyl, metal, PVC, and fabric. It works seamlessly with thermal and piezo inkjet systems for banners, posters, and textiles. This compatibility allows businesses to use existing equipment without significant modifications, ensuring flexibility and enhancing efficiency.

3. Cost-Effectiveness

Solvent ink printing is not only durable and versatile but also cost-effective. Its long-lasting prints and efficient process reduce overall costs. Compared to other types of ink for printers, solvent-based inks require fewer replacements and can print on uncoated media, lowering material costs. Their fast-drying properties ensure high production uptime, allowing continuous production and keeping projects on time and within budget.

Challenges and Limitations of Solvent Ink Printing

It offers durability but has challenges like high VOC emissions, regular maintenance needs, and material compatibility issues. Users must weigh these factors when deciding if solvent ink is the right choice.

Environmental and Safety Concerns

Solvent-based ink printing uses volatile organic compounds (VOCs) that can harm human health and contribute to air pollution. Exposure can lead to skin irritation and respiratory issues. Proper ventilation, protective gear, and handling protocols are essential.

- Regulations from the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) aim to reduce VOC emissions from solvent-based inks. These guidelines promote safer practices and encourage the use of eco-solvent inks, which release fewer VOCs.

- Safety Measures: To mitigate health risks, use protective gear (gloves, masks) and ensure proper ventilation. Store and dispose of ink waste properly, and maintain equipment regularly for safe operation.

Limitations on Material Types

Solvent-based ink works best on non-porous materials like vinyl, PVC, and synthetic fabrics, which allow for better adhesion. However, it struggles with porous surfaces such as paper or textiles, where ink may not adhere properly, leading to poor quality and fading. Therefore, selecting the right materials for solvent printing is essential to ensure optimal results.

Printer Maintenance Requirements

This printer ink requires regular maintenance, including cleaning to prevent clogging and ensuring color accuracy through calibration. This ongoing upkeep can lead to additional costs and time, which businesses must consider when using solvent printing for high-volume production.

How to Choose the Right Solvent Ink Printer

Choosing the right solvent ink printing system depends on factors like ink type, material compatibility, printer maintenance, and production scale. When choosing a printer ink solvents system, consider the following factors:

- Print Size & Volume: Match your requirements with the printer’s capacity for large or small prints.

- Material Compatibility: Ensure the ink suits materials like vinyl, canvas, or PVC.

- Budget & Maintenance: Account for initial costs and ongoing maintenance, including printhead cleaning.

- Printing Process: Select the ink based on the printing method and substrates.

- Environmental Considerations: Opt for low-VOC or eco-friendly inks for sustainability and regulatory compliance.

Conclusion

Printing Ink Solvents are reliable and durable solutions for various materials, offering high-quality results. While eco-solvent ink is emerging as a more eco-friendly option due to lower VOC emissions, traditional solvent ink remains strong for outdoor signage and vehicle wraps. Choosing the right ink depends on specific needs, including material compatibility and sustainability goals. With advancements in eco-friendly options, the future of solvent ink printing offers a balance between performance and environmental responsibility.

Interested in sustainable and efficient printing solutions? Contact us today at Compandsave to find the perfect ink and start printing with confidence!

Frequently Asked Questions

1. Are solvent inks harmful and unsafe?

Eco-solvent inks are a safer and more environmentally friendly alternative to traditional solvent inks. They emit fewer VOCs, making them safer for both the user and the environment while still maintaining high-quality print durability.

2. Is solvent ink only for outdoor applications?

No, solvent ink is versatile and can be used for both indoor and outdoor applications, including vehicle wraps, signage, and textile printing. Its durability makes it ideal for projects exposed to outdoor elements, but it performs well in indoor settings too.

3. Are solvent inks expensive?

While solvent ink may have higher upfront costs, eco-solvent inks offer a cost-effective option with similar performance and quality. Over time, solvent inks provide long-lasting, weather-resistant prints, ensuring value for money on large-scale and high-demand projects.

4. Does using solvent ink require excessive maintenance?

Solvent-based printers require regular maintenance, including cleaning of printheads and ink lines, to prevent clogs. However, with proper care, maintenance is manageable and ensures consistent print quality, making solvent printing a reliable choice.

5. Are solvent-based inks environmentally harmful?

Traditional solvent inks emit higher levels of VOCs, which can harm the environment. Eco-solvent inks, however, are more eco-friendly with reduced VOC emissions and biodegradable solvents, making them a greener choice while maintaining print durability and quality.

Related Articles

Eco-Friendly Ink Cartridges: Print With A Purpose

Eco-Friendly Printing: How It Works and How You Can Help